how is the brinell hardness test performed|brinell hardness testing machine diagram : distributing Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .

18 de setembro de 2023, 19:22 75.7k Views 1. Vazou nudes vídeo da Catarina Paolino no onlyfans, essa gostosa sedutora troca de blusinhas arias vezes marcando o biquinho do .

{plog:ftitle_list}

webOFICINA DO CELULAR,SE ENCONTRA NA RUA REINALDO MASSI 1060 SOMOS. Oficina Do Celular - Rolândia, Rolândia. 693 likes · 1 talking about this · 18 were here. OFICINA DO CELULAR,SE ENCONTRA NA RUA REINALDO MASSI 1060 SOMOS ASSISTÊNCIA TÉCNICA, TEMOS PELÍCULAS

The Brinell hardness test formula. When measuring hardness using the Brinell method, a hardened steel or carbide ball of known diameter under a known load is forced into the .

The Brinell hardness test is based on the amount of resistance that a solid material offers when it is pressed into by force. Brinell’s method produces a small . There are two methods to perform the Brinell hardness Test on the metal as follows: Standard Method. Non-Standard Method. Standard Brinell Hardness Test: Brinell Indentation Diagram.The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .The Brinell scale / b r ə ˈ n ɛ l / characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science.

Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading .The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to 3000Kgf, for a specified time period, usually .The Brinell method is a static hardness testing method, which can be characterised as follows: It is one of the standardised procedures (ISO 6506, ASTM E10). The Brinell method has a .

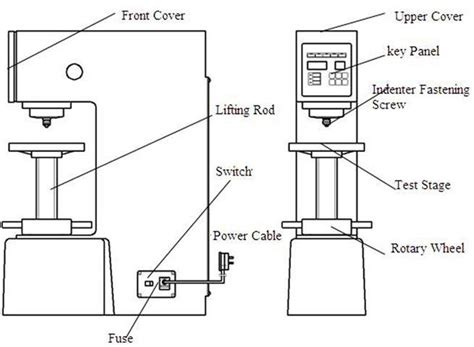

brinell hardness testing machine diagram

Basic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition .Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information .This eLearning course focuses on Rockwell and Brinell hardness testing and Vickers and Knoop microhardness testing. Participants will learn about how the tests are performed, test sample requirements, test parameter selection, and testing requirements. The course can be completed in 30 minutes.In the Brinell test, hardness is defined as load divided by the curved area of the indentation; in the Vickers test, the diagonal of the square impression is measured. The Vickers test was in due course miniaturised and mounted on an optical microscope to permit microhardness tests on specific features of a microstructure, and this has been .

The Brinell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .

Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .In metallurgy: Testing mechanical properties .oldest of such tests, the Brinell hardness test, uses a 10-millimetre-diameter ball and a 3,000-kilogram load. Brinell hardness values correlate well with UTS. The Brinell hardness test is not suitable for very hard materials or hardened surface layers because the ball does not penetrate sufficiently into the material. Higher test loads are not the solution at this point, as this leads to deformation of the carbide ball. The flattening of the ball results in a larger indentation diameter and thus .The Brinell hardness testing method is used in various cases where large or rough surfaces, coarse-grained materials, or high loads are involved. It is particularly well-suited for testing the hardness of materials with relatively low hardness ranges, such as non-ferrous metals, castings, and softer steels.

The Brinell hardness test was developed by the American Henry Brinell, who created the first tester in 1873. This is a widely accepted method in the field. The ASTM’s Brinell hardness test standard is used by alloy and metal suppliers and users, and it’s a basic requirement for all hardness testing equipment. This method was invented in 1900 by the Swedish engineer Johan August Brinell, becoming the first scientific procedure for measuring penetration hardness. How is a Brinell hardness test performed? In a Brinell test, the estimation of hardness takes place through the process known as indentation. It consists of applying an object (indenter or . The Brinell hardness test measures material hardness by determining the diameter of an indentation made by a hardened steel or carbide ball under a specific load. A load, typically ranging from 500 to 3,000 kgf, is applied to the material’s surface for 10-15 seconds, allowing the ball to penetrate and create an indentation. .

The Brinell hardness test is an optical testing method for samples with coarse or inhomogeneous grain structure. This is the best test method for achieving the bulk or macro-hardness of a material, particularly those materials with heterogeneous structures.Application of Brinell Hardness Test in Various Industries. The Brinell Hardness Test finds extensive application across diverse industries, playing a crucial role in assessing material hardness and ensuring the quality and reliability of products. Below are some key industries where the Brinell Hardness Test is commonly employed. 1. ManufacturingAn alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:

History Behind the Brinell Test. Let’s take a quick glance at the history behind the Brinell test. In 1900, Dr. J.A. Brinell invented this test. As an honor to him, the test named as a Brinell test. It is the oldest hardness test of all time. .Apparatus Brinell Hardness Testing Load Meter Universal Tester Page 8 of 13 Procedure For Brinell Hardness Testing • Brinell hardness testing is typically done on iron and steel casting using a 3000kg test force and a 10mm .II. Principle and Theory of Brinell Hardness Test. Brinell hardness testing uses a known-sized ball with a diameter of 10mm and is pressed into the material with a specified amount of force. The smallest indentation made into the material is then measured and recorded.

The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. The indentation diameter is then measured optically. The Brinell hardness number (BHN) is calculated as the load .Brinell Hardness Test: Using a spherical indenter, this test determines the hardness by measuring the diameter of the indentation created by a known force. It’s suitable for materials with coarse grain structures or rough surfaces. . This method finds utility in scenarios where conducting a static hardness test (typically performed on a . 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .

3.1.4 Brinell hardness test—an indentation hardness test using a verified machine to force an indenter (tungsten carbide ball with diameter D), under specified conditions, into the surface of the material under test. The diameter of the resulting indentation d is .

The Brinell hardness test method as used to determine Brinell hardness is defined in ASTM E10. It is typically used to test materials with a structure or surface too coarse to be tested by any other test method, for example castings and forgings. Brinell tests often use a very high test load (3000 kgf) and a 10mm diameter indenter so that the .8, A Brinell test is performed on a metal sample. A 3000 kg load applied for 30 seconds on a 10 mm tungsten carbide ball leaves an indenta- tion of 9.75 mm in the sample. Calculate the Brinell hardness and determine where it fits on the Moh hardness scale.Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter . General Information about the Brinell Hardness Test. The Brinell hardness test involves pressing a hard ball indenter, usually made of tungsten carbide, into the material’s surface with a specified force. The diameter of the ball is typically 10 mm, but smaller diameters such as 2.5 mm can also be used for specific applications.

The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression is measured with a microscope with a superimposed scale. The Brinell Hardness Number HB is computed from the equation: where P is the applied load of 3,000, 1,500, or 500kg. D is the diameter of the ball in mm. (10mm)Question: In a Brinell hardness test, a 1500-Kg load is pressed into a specimen using a 10-mm diameter hardened steel ball. The resulting indentation has a diameter = 3.2 mm(A) Determine the Brinell hardness number for the metal (B) If the specimen .

brinell hardness testing charts

brinell hardness tester diagram

oil or water based paint test

webPlan your trip with Google. Find flights, hotels, vacation rentals, things to do, and more.

how is the brinell hardness test performed|brinell hardness testing machine diagram